Civil 3D’s Property Sets have been around for a while now, and if you’re working on a BIM project,they are fundamental for adding additional asset data to both Civil 3D and AutoCAD objects.Property Set data will be included with objects when a model is exported to IFC or Navisworks.

Here are some tips and examples to help you make full use of Property Sets in Civil 3D.

Labels and Tables

Property Sets can be used for adding annotation to Civil 3D drawings. When Property Set data is added to a Civil 3D object, its fields are made available in the Label Text Component Editor.

We can also add the same information to Tables, although the Property Set data isn’t exposed in the Table Editor. To addthis data to a Table Column, type the required field into the Component Editor as follows:

<[PS:Pipes:Bedding(CP)]>

Where Property Set denotes Property Set data, Pipesis the name of the Property Set, and Bedding is the name of the field. The (CP) is a formatting field which in this example denotes Capitals Preserved.

Using Pick Lists

For many types of data, we would want to restrict the user to a specific list of possible values. This can be achieved by adding a List to our Property Data.

In the Style Manager, turn off the Filters.

This gives us access to more features, one of which is the List Definitions.

In this example, we’ve added a new list for Pipe Bedding. The list “Applies To” setting must be assigned to “Manual Property Definition.”

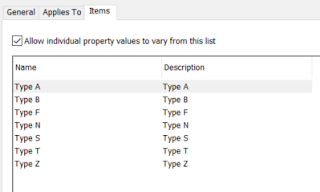

Items can then be added to the list as

required.

In the Property Data set, the list can be accessed by adding a manual property, and then choosing the “List” option for the Type of field.

Notice that there is a Formula field whose source is set to the new Bedding_Class property. This is required as a List field and cannot appear in a Civil 3D label, but the Formula field will do.

After adding this Property Set to Pipes in

the drawing, the user can select a value from the defined list.

VBScript in Formulas

Complex data fields that can read properties of objects and manipulate data can be created by using VBScript in formula fields. One of the issues you may find is knowing what commands are available to you, but the VBScript Code helper is empty.

The information that populates this is saved in an XML file. Since the Property Set feature has been “borrowed” from AutoCAD Architecture, the definition file is still available. It can be downloaded from this link:

Copy the file into C:\Program Files\Autodesk\AutoCAD 20XX folder.

The helper will then be populated as shown:

VBScript can be used to retrieve data from

Civil 3D objects by making use of the Civil 3D API.

Here’s a straightforward example that

creates a field that displays either a manhole diameter or length x width,

depending on whether it is a circular or rectangular structure.

RESULT="--"

On Error Resume Next

Set oApp=GetObject(, "AutoCAD.Application")

Set

oCivilApp=oApp.GetInterfaceObject("AeccXUiLand.AeccApplication.13.0")

Set obj=oCivilApp.ActiveDocument.ObjectIDToObject([ObjectID])

If obj.BoundingShape = 1 Then

Result = CStr(obj.StructureInnerDiameterOrWidth*1000)

Else

Result = Cstr(obj.StructureInnerLength*1000) + " x " +

CStr(obj.StructureInnerDiameterOrWidth*1000)

End

If

The Civil Application must be set to the correct value depending on the version of Civil 3D you’re working on.

The following codes are valid for these versions:

2018 - 12.0

2019 - 13.0

2020 - 13.2

To use the code snippet shown above, the Object ID of the structure must first be defined as a property field using an Automatic property definition.

Property Set Commands

Aside from using the Manage ribbonto access the Property Set definitions, there are several commands you can benefit from using on the command line:

AECPSDAUTOATTACH OFF or ON – automatically assigns property sets to relevant objects

PropertyFormatDefine Calls up the Style Manager interface

PropertyData Combines some of the commands in a command line version

PropertyDataBrowse A useful command to see where property data has been assigned to objects

PropertyDataEdit Edit property data on selected objects

PropertyDataExt List and edit attached property data on a selected object

-PropertyDataEdit Scriptable command line version to edit property data on selected items.

PropertySetDefine Calls up the style Manager with Property Set definitions

PropertySetClean Removes a Property Set from object types to which it no longer applies

PropertySetAccess Edits the visibility and permissions of Property Sets. Used by the IFC Export –Do not use this command!

PropertySetDefSync Do not use this command!(Except perhaps as a last resort if your Property Data is really messed up!)

PropertySetDump Dumps the Property data and other information to the screen

PropertySetDefMerge Combines Property Set definitions

ExportPropertyData Exports Property Data to a Microsoft Access database

I hope you find this post useful. For other useful information and blogs on Civil 3D, visit our website here.

If you require any further information on Civil 3D, please feel free to get in touch by calling us on 01992 807 444 or emailing info@symetri.co.uk.