Each year Autodesk releases an improved version of Autodesk Revit, with new features. Today, I will focus on new features specifically for structures.

In the Autodesk Revit 2023 release, the structural tools build on the core functionality of reinforced concrete modelling and steel fabrication modelling, but also the new analytical automation. Here are the key features and tools relating to concrete and steel modelling.

Visualisation of Rebar in 3D View

Making rebar visible in a 3D view has been

simplified. With the rebar selected, in the view visibility states dialogue box,

you only have the view unobscured option to tick. The rebar will automatically view

as a solid when your view is in the Fine Level of Detail.

Propagate Rebar

A new feature is the Propagate Rebar; with the rebar

selected in a host object, the propagate rebar tool will appear. You can select

individual or multiple ‘like’ hosts to copy the rebar.

Displaced Rebar

A pasted feature that now works with rebar,

select the rebar in a host object and use the standard displace elements tool

to reposition the rebar in your view as desired. You can add path lines and

reset the displaced bars.

Multi Leader Tags for Rebar

Use the standard tag by category tool to tag a

rebar set, you can add additional bars from that set to the tag; you can also control

the leader lines with multi or single leaders.

Analytical Automation

In Autodesk Revit 2023, we now have Analytical

Driven Modelling; this differs from the derived analytical model as contextual,

analytical elements are not created automatically when the physical model is

created. We have new feature capabilities such as Analytical Member, Analytical

Panel, Analytical Node, and Analytical Openings.

We also have a new Automation feature to

generate a structural analytical model based on selected physical elements.

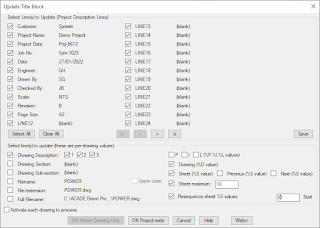

Steel Connections Automation

To learn more

about Autodesk Revit, please visit our product page or call us on 0345 370 1444 or

email info@symetri.co.uk.